MIL-DTL-46035C(MR)

3.4.1.1.1 Maximum yield strength. The specified yield strength range may be exceeded providing

the percent elongation, percent reduction in area, and V-notch Charpy impact resistance do not fall

below values specified in table II for the upper limit of the specified yield strength range.

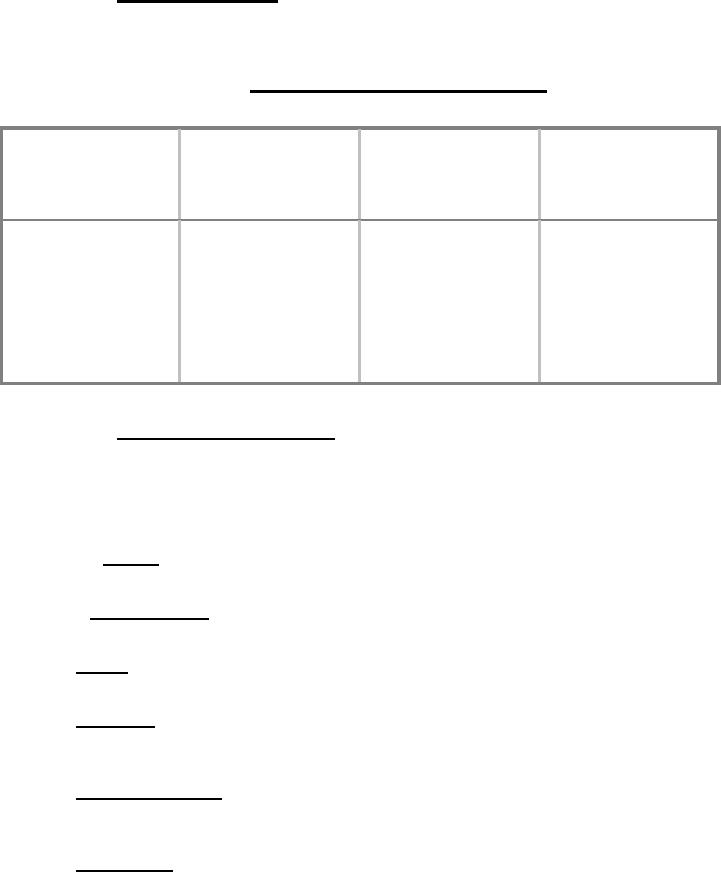

TABLE II. Minimum mechanical property requirements.

Transverse direction

V-notch

Yield strength

Average

Charpy impact

increments

Average

reduction

resistance

(0.2% offset)

(at -40 °F)

elongation

in area

(ft.lb)

(psi)

(percent)

(percent)

120,000 - 129,999

13

25

13

130,000 - 139,999

11

23

11

140,000 - 149,999

10

21

10

150,000 - 159,999

10

21

10

160,000 - 169,999

8

15

8

170,000 - 179,999

6

13

6

180,000 - 189,999

6

13

6

190,000 - 199,999

5

12

5

200,000 - 210,000

5

12

5

3.4.1.1.2 Elevated temperature properties. For applications requiring elevated temperature

properties, the contractor shall demonstrate, by presenting published data or conducting special tests

that the proposed alloy will meet a minimum transverse yield strength (0.2% offset) requirement of

140,000 psi at 300°F. In addition, the elongation, reduction in area, and V-notch Charpy impact

resistance shall be equal to or greater than the values shown in table II opposite the 170,000-179,999

psi strength range.

3.4.1.2 Ductility. The reduction in area and elongation requirements shall be as specified in table

II for the applicable yield strength range.

3.4.2 Impact resistance. The V-notch Charpy impact resistance shall be as specified in table II

for the applicable yield strength range.

3.5 Density. The maximum density of titanium alloy shall be 4.70 grams per cubic centimeter.

Certification of the density shall be provided by the contractor.

3.6 Dimensions. Dimensions and dimensional tolerances shall be as specified on the applicable

drawing or contract, plus any prolongation (see 6.3.2) which is an integral part of the piece as heat

treated.

3.7 Identification marking. Unless otherwise specified (see 6.2), each piece shall be legibly and

indelibly marked with the piece number, heat number, or designation, the number of this specification,

and the manufacturer's identification.

3.8 Workmanship. The titanium alloys shall be uniform in quality and condition; free from seams,

injurious segregations, cracks and other defects which, due to their nature, degree or extent, would

detrimentally affect the suitability of the material for the intended use.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business