MIL-DTL-46035C(MR)

ASTM E8

Tension Testing of Metallic Materials (DoD adopted)

ASTM E21

Elevated Temperature Tension Tests of Metallic Materials (DoD adopted)

ASTM E23

Notched Bar Impact Testing of Metallic Materials (DoD adopted)

ASTM E120 Chemical Analysis of Titanium and Titanium Alloys (DoD adopted)

(Application for copies should be addressed to the American Society for Testing and Materials, 100

Barr Harbor Drive, West Conshohocken, PA 19428-2959.)

2.3 Order of precedence. In the event of a conflict between the text of this document and the

references cited herein, the text of this document takes precedence. Nothing in this document,

however, supersedes applicable laws and regulations unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 Chemical composition. Unless otherwise specified in the contract, the chemical composition

of the titanium alloys shall comply with the range proposed by the supplier. The supplier shall submit a

certified analysis of each heat to the procuring activity. The statement of analysis shall include all

elements intentionally added as well as the percentage of oxygen, hydrogen, and nitrogen present as

impurities, and the percentage of iron and copper present. Three grades with respect to impurities may

be specified in the invitation for bids or contract as shown in table I.

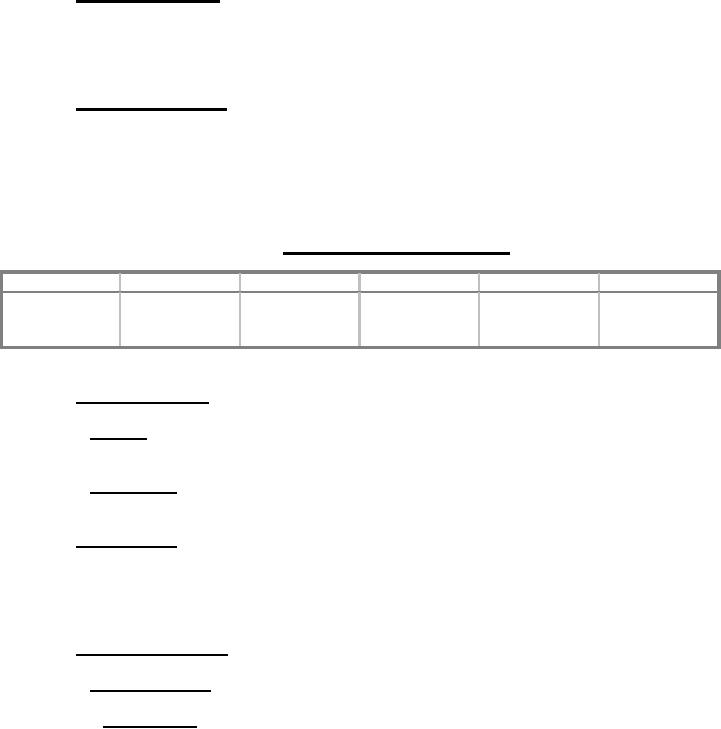

TABLE I. Composition - percent, maximum.

Impurity

Grade

C

O2

N

H

Extra low

EL 1

0.10

0.10

0.02

0.0125

Low

L1

0.10

0.12

0.03

0.0125

Normal

N1

0.10

0.18

0.04

0.0125

3.2 Processing controls.

3.2.1 Welding. Components shall not be welded, except on prolongations. All welds shall be so

located that they will not affect the finished components or the test metal.

3.2.2 Straightening. The material shall not be straightened or worked after the final heat treatment

operation.

3.3 Heat treatment. Heat treatment, (solutionizing, cooling, stress-relieving, and aging) shall be

performed uniformly on the material being processed. Unless otherwise specified (see 6.2), the

quenching of tubular components shall be done vertically with the bore unobstructed, so as to permit

free passage of the coolant through the bore. Aging shall be performed at a temperature of not less than

500°F, and for a sufficient time to ensure uniform response throughout the section.

3.4 Mechanical properties.

3.4.1 Tensile properties.

3.4.1.1 Yield strength. The yield strength shall be as specified in the contract, or on the applicable

drawings.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business